In the energy transition, enormous projects such as developing green ammonia terminals, hydrogen plants, and CO2 capture and storage facilities are being developed. This is increasing the number of megaprojects. Common contract forms for these mega-projects are: “Engineering, Procurement, and Construction” (EPC) and “Engineering, Procurement, and Construction Management” (EPCM).

Although EPC and EPCM appear similar at first glance, there are fundamental differences between the contracting strategies. Successful execution of these mega-projects requires close collaboration between the various parties involved, including “asset owners”, contractors and consultants; this requires a well-considered contract strategy. What are the differences?

What is EPC?

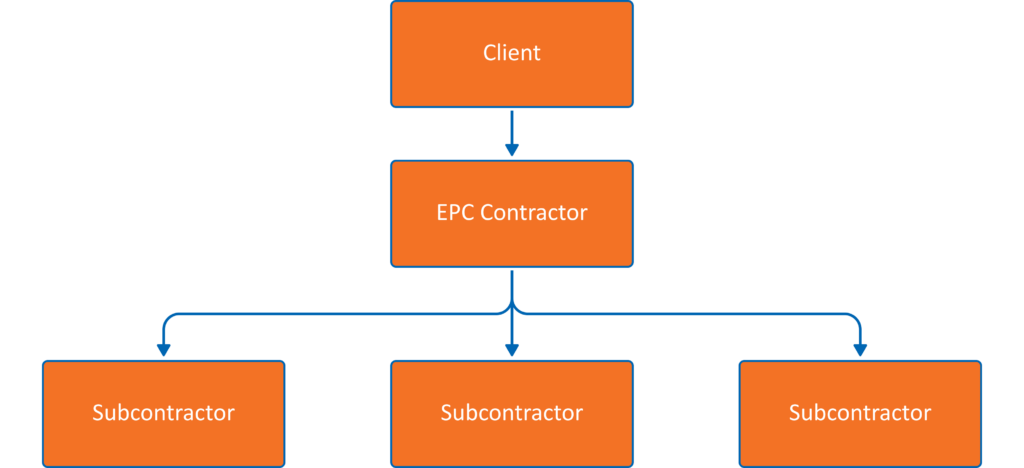

An EPC contract derives from Engineering, Procurement, and Construction (design, procurement and construction). The EPC contractor enters into a performance commitment to achieve specific results. For example, the EPC contractor must complete the project within the specified time and budget.

In international projects, FIDIC conditions are often used for this purpose. For Dutch projects, the Uniforme Administratieve Voorwaarden voor Geïntegreerde Contractvormen (UAV-GC) are often used here. This is an integrated contract where the contractor is responsible for the design and its execution. The EPC contractor bears full responsibility for design, procurement of materials, and construction. The EPC contractor is also the central point of contact within the project. This principle ensures clear risk allocation, where the EPC contractor has limited opportunities to claim additional cost reimbursement and/or deadline extension. The client has a minimal share in day-to-day project management. Despite the EPC contractor charging a premium, this approach provides a high degree of certainty for the client (and financiers).

What is EPCM?

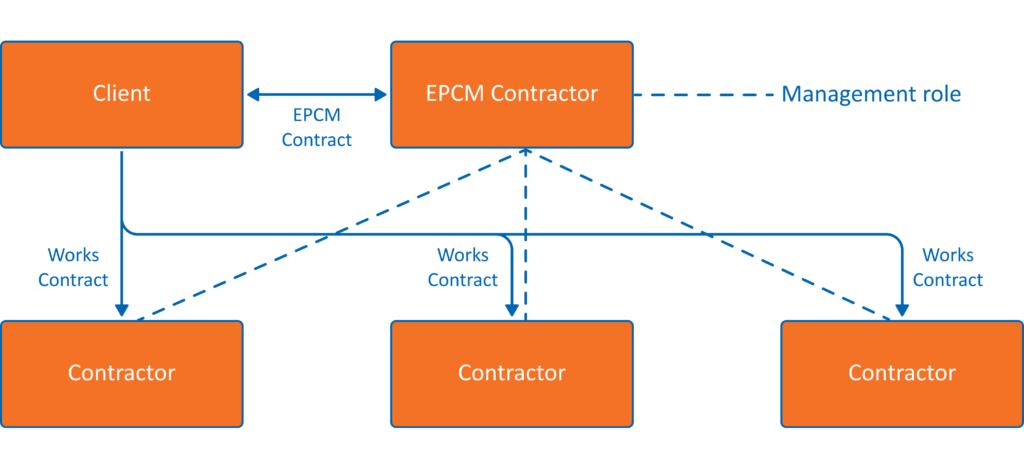

Within the EPCM model, derived from Engineering, Procurement, and Construction Management (design, procurement and construction management), the EPCM contractor does not directly participate in the construction or the construction work.

Unlike the EPC model, where a single contractor is responsible, in the EPCM model several suppliers and contractors are engaged on behalf of the client to perform specific tasks. An EPCM contract is characterised as a service agreement, where the EPCM contractor has a best-efforts obligation. The EPCM contractor typically performs the following services:

- Design (this includes producing “basic engineering” and developing the detailed design).

- Procuring materials and contracting work on behalf of the client.

- Construction supervision and coordination between contractors and suppliers.

The EPCM contractor provides project management services during the project without being a risk-bearing principal per the contract. The EPCM contract, unlike EPC, gives both the EPCM contractor and client more flexibility to make changes to the design and/or execution methods during execution. There is currently no standard set of general conditions tailored specifically to the EPCM model in the Netherlands. This is also limited internationally. FIDIC terms and conditions are often used internationally in the underlying contracts for the executing contractors. In the Netherlands, the standard Uniform Administrative Conditions 2012 (UAV) are also used for this.

Key differences between EPC and EPCM contracts

EPC

- Full project responsibility lies with the EPC contractor. The EPC contractor bears the sole financial risk for the construction.

- One point of contact and communication.

- Minimal involvement from the client, but a high premium on making adjustments/changes.

- Technical scope should be defined as much as possible in the EPC contract due to the high risk of exceeding budget and deadlines.

EPCM

- Financial risk for construction lies with the client.

- Client retains more control over project management.

- EPCM contractor acts as consultant and coordinator for engineering, procurement and construction.

- More influence and control at each stage of construction by client, but higher risk of claims due to interfaces between contractors.

In both EPC and EPCM, a skilled team from the client is essential to manage contractors and make the right technical decisions in a timely manner.

This is how you decide which project form to choose

Which project form is most appropriate for your project and best meets the needs of the organisation? A contract strategy is used to determine which contract is most appropriate for the project. This involves considering a number of key elements, such as the complexity and status of the design, and the client’s ability to manage all phases of the project. Making the right choices during a contract strategy is critical and can have a significant impact on the success of the project.

What is the best choice for my project?

Every project is unique, so there is no universal rule for choosing the best approach in a contract strategy. The choice between EPC or EPCM depends on the specific project needs, desired level of client involvement, and desired risk allocation.

Projects with many variables and specialisations may benefit from the flexible nature of the EPCM model, while standardised projects are probably better suited to the EPC model. Moreover, the choice between the different models depends heavily on the robustness of one’s own organisation. It is very important to understand the advantages and disadvantages, as this forms the basis of a successful project course.

Vijverberg has extensive experience in developing contract strategies for complex construction projects. Wondering what we can do for your project? Please contact Jan-Willem van Beek.