Every project encounters events that lead to delays or disruptions. The responsibility of an event that cases delay may lie with the contractor, with the client or with both. To answer the question of responsibility, you will need to identify the causes of the delays and disruptions and individually understand their effect relative to the project schedule. Finally, you will need to assess the joint effect of the delays and disruptions.

In this best practice, we outline the methodology for determining delay by cause (event). The aim is to objectively determine what part of a delay can be attributed to client or contractor.

Forensic Schedule Analysis

The methodology that you use to understand the effect of delays and disruptions is called Forensic Schedule Analysis. The American Association of Cost Engineers (AACE) has established an internationally recommended practice for delay analysis: AACE® International Recommended Practice No. 29R-03 Forensic Schedule Analysis (2011). Several methodologies are detailed in it.

The methods

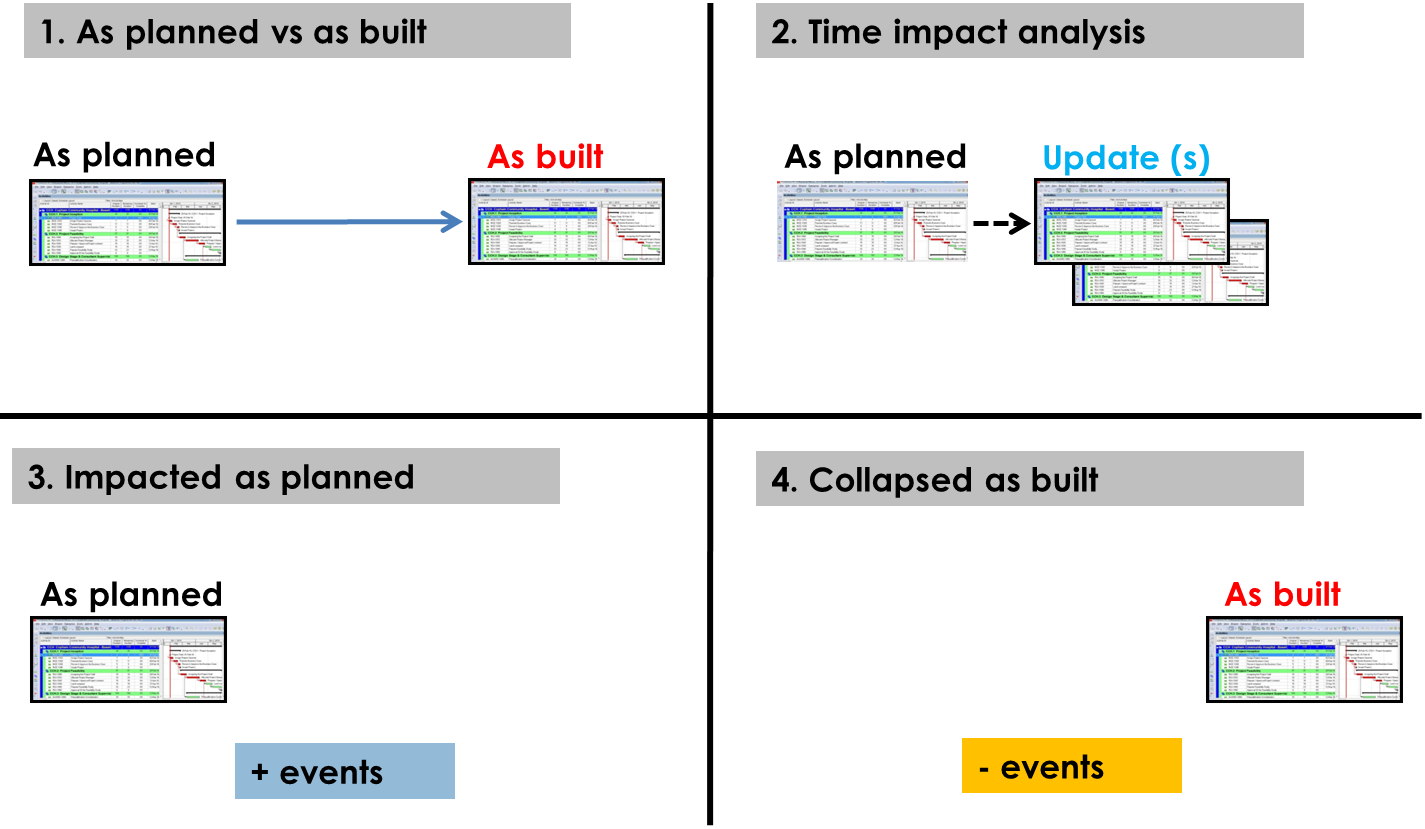

As planned versus as-built

The as-planned versus as-built method compares baseline planning with as-built data, evaluating any impact on the critical path. The baseline schedule is the schedule that includes all the work according to the original contract (without additional and reduced work). Preferably, this baseline schedule is accepted by contractor and client. The as-built data can be a combination of planning updates, (inspection) reports, construction reports, photographs, and correspondence.

Time impact analysis

The time impact analysis method compares baseline planning with schedule updates. Changes to, for example, the construction sequence and critical path become clear when comparing multiple schedules.

Impacted as planned

The impacted as planned method adds the event to the schedule. If the completion date shifts after the event is included in the schedule, then it is caused by the event. If the delivery date does not shift, the event does not cause delay and is a disruption.

Collapsed as-built

The collapsed as-built method assumes the as-built schedule and removes the event from the schedule to determine the effect on the completion date.

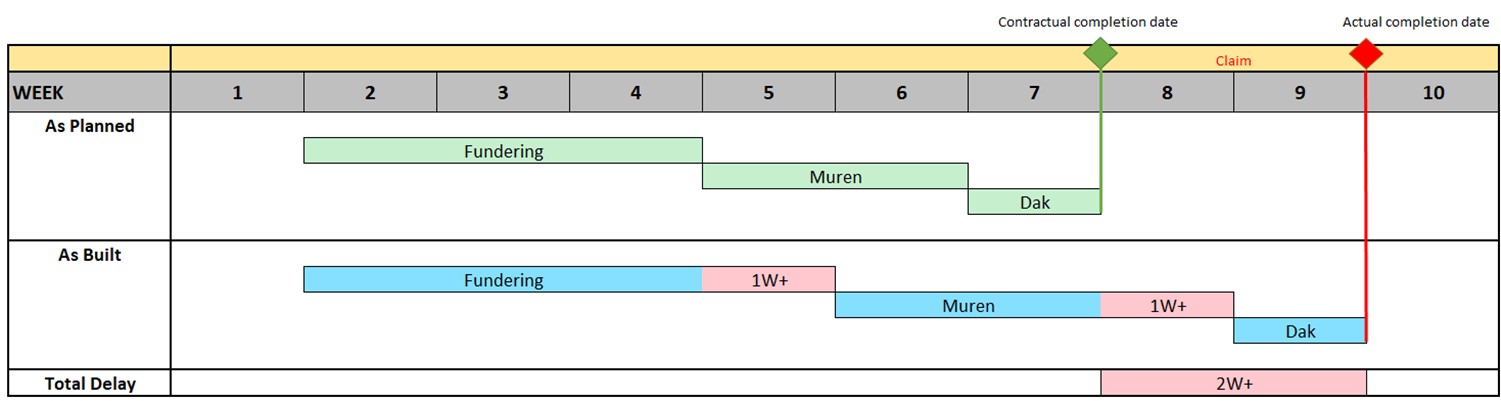

The figure below illustrates the comparison of as-planned versus as-built, as referred to in methodology 1.

Action plan

1. Determine the methodology

The choice of methodology depends on the purpose of the analysis, the availability and reliability of the data, the size and complexity of the project. The methodology may also be prescribed in the contract.

2. Describe the event and determine the impact per event

In addition to the description, also indicate the day on which the event occurred and the end date of the event. You can get this information, for example, from construction reports or e-mail correspondence.*

3. Determine the impact of the joint events

If there is concurrence (competition) of delays, you should apply an offset. Ultimately, a contractor may have to pay a rebate on part of the delay and receive a construction time extension with reimbursement of costs for another part.

*To determine the impact of the event, you can use the following questions:

- Which activities cannot be performed as a result of the event?

- What activities can be performed in parallel with the event?

- Does the event lead to new activities?

- Does the event lead to the cancellation of activities?

- Does the event lead to adjustment of lead times of activities?

- Does the event lead to adjustment of the sequence of activities?